Can bonded solid lubricants preserve the teeth of running clocks?

This post was written by Oliver Cooke

Antiquarian clocks are still in widespread use. However, like any machine, mechanical clocks wear out as they run and, to keep them running, repairs will inevitably be necessary.

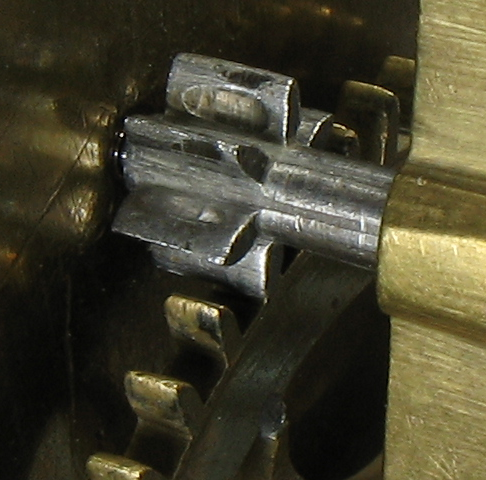

The image above shows a three century old longcase clock pinion that is well worn. Such a change in form will hinder the correct running of the clock until, eventually, it may no longer run at all.

Current repair techniques involve replacing the lost material or the whole gear. Either method is likely to result in loss of evidence of the clockmaker’s original work. This information is important as it can help us to assess the authenticity and origins of clocks.

It would therefore be useful to find a way to reduce the wearing of the teeth in the first place.

Liquid lubricants, e.g. oils, are generally not used on the teeth of clock gears as they are typically exposed to the air, from which dust can mix with the oil to form an abrasive, or chemicals can form which can corrode gears.

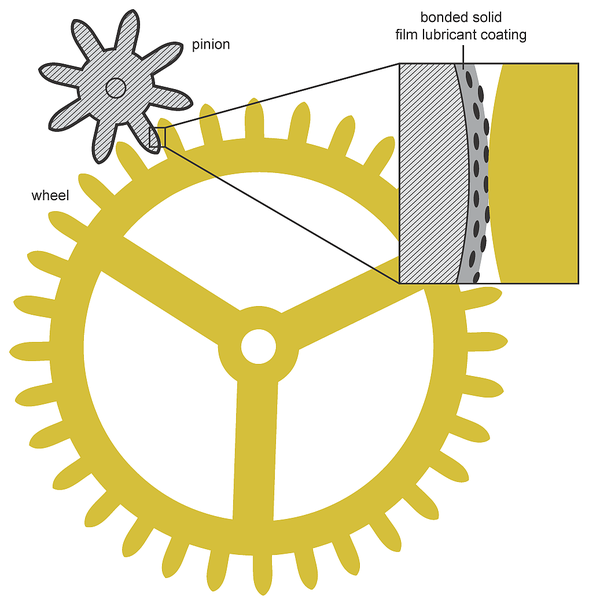

Bonded solid lubricants (B.S.L.s) are dry and do not absorb contaminants from the air. B.S.L.s contain particles of dry lubricant, such as graphite, suspended in a binding agent, such as epoxy resin.

They are applied as a liquid which cures to form a hard, dry coating. This coating can both lubricate and act as a sacrificial wearing layer. B.S.L.s might therefore be a useful treatment for preserving the gears of clocks.

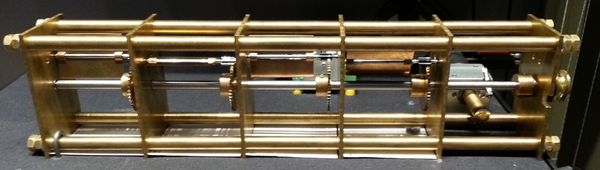

Over the last year at the British Museum, where we run antiquarian clocks in the gallery, I have been conducting trials of B.S.L.s on model gear teeth as part of an MA Programme in Conservation Studies at West Dean College.

The B.S.L. that was tested was found to reduce wear compared to uncoated gear teeth. However, scientific analysis showed that it contained chemicals that are unsuitable for use on historic parts.

There are however many other types of B.S.L. and, given the promising results, I plan to test more. It is hoped that this will eventually lead to a treatment to help to keep the antiquarian clocks running with their original gears.

Look out for more information in future editions of our journal, Antiquarian Horology.