The AHS Blog

Clockpera at the British Museum

This post was written by Oliver Cooke

The pairing of clocks and opera has been a recurring theme in this blog (1, 2, 3) and I am now happy to report on another such coincidence.

Over recent years, members of an opera production company, Brolly Productions, have made several visits to horological study room at the British Museum (where I work).

They came to look at different kinds of clocks and understand how they work, in order to provide a solid foundation for the design of their latest production, “CLOCKS 1888: The greener”.

The lead character is a 'greener', i.e. 'an immigrant who has only recently arrived', who were common to East London in the 19th century in which the opera is set.

She is responsible for maintaining the clock that controls the workforce of the East End but she comes under pressure from her overseer to alter its running to increase production.

Also, 'of course it is an opera, so there has to be a love story' says Dominic Hingorani, Librettist & Director of Brolly Productions.

Last Friday lunchtime, in the horological gallery of the BM, an event was held to celebrate the collaboration.

The highlight of this were two songs from the production, performed by Keisha Atwell, who plays Greener. Freddie Matthews, Head of Adult Programmes of the BM, introduced the event.

Dominic then spoke about the evolution of the production. Rachana Jadav, Designer & Illustrator of Brolly Productions, spoke of the creation of the design, including the influence of the BM clocks.

Also speaking was Paul Buck, Curator of Horology of the BM, who told how the horological team embraces access to the collection and will consider even the most diverse requests. Indeed, access to the collection is available to all students, not only horologists.

Members of the AHS have the opportunity to visit the horological study room for talks from the curators and close-up viewing of objects. These group visits are organized by the AHS’s regional sections.

CLOCKS 1888: The greener is playing at CAST Doncaster, Fri 15th April to Sat 16th April 2016 and at the Hackney Empire, Wed 20th April to Fri 22nd April 2016.

Donation to the British Museum

This post was written by Oliver Cooke

I write with a foot in two allied camps: as a member of the AHS and a Curator of Horology at the British Museum.

In October last year the AHS Council generously donated sixteen interesting clocks, watches and horological tools to the BM collections. The items had in fact been at the BM since 1973, having been deposited on long-term loan when the AHS left its former London HQ.

This conversion to a donation consolidates that loan and upholds one of the core objectives of the AHS which is the support of public collections.

Let us look at three of the items.

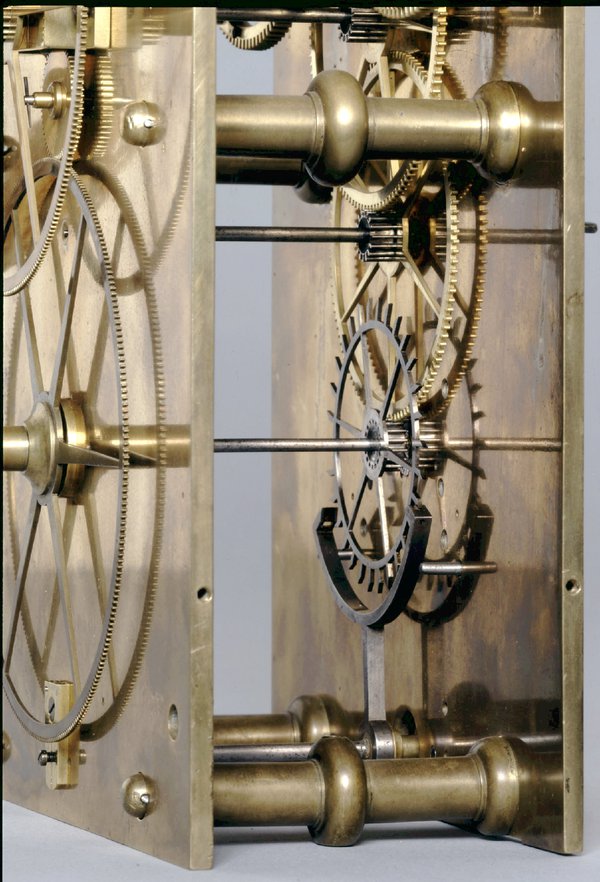

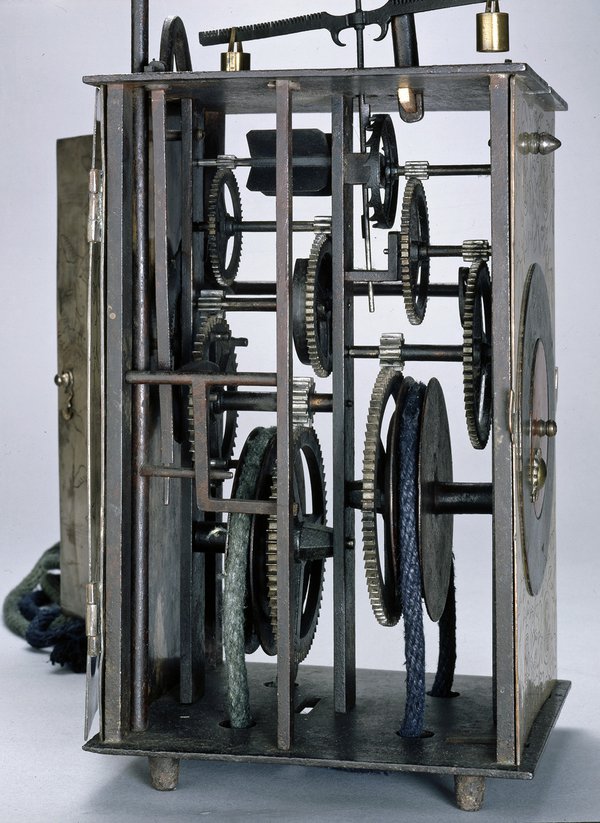

Firstly, a lantern clock with centre verge pendulum by Johannes Kent of Congleton, Cheshire, late 17th century.

Lantern clocks with centre pendulum sometimes had 'angel wing' extensions to the side doors to accommodate the arc of pendulum. This clock does not have these, but the side doors (which seem to be later) do not interfere with the action of the pendulum.

Unusually for this time, the clock does not have Huygens’s endless winding system, but has a separate drive for each train.

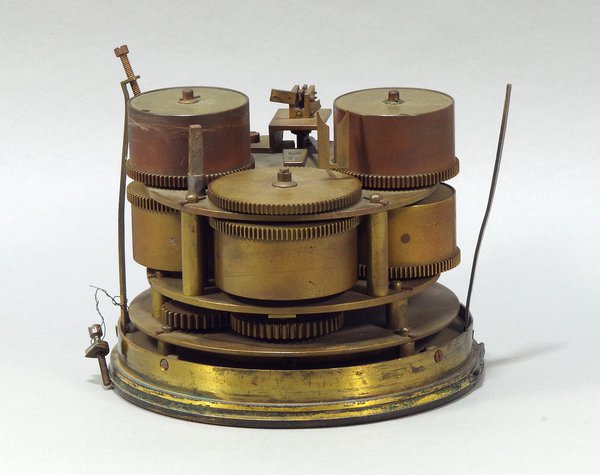

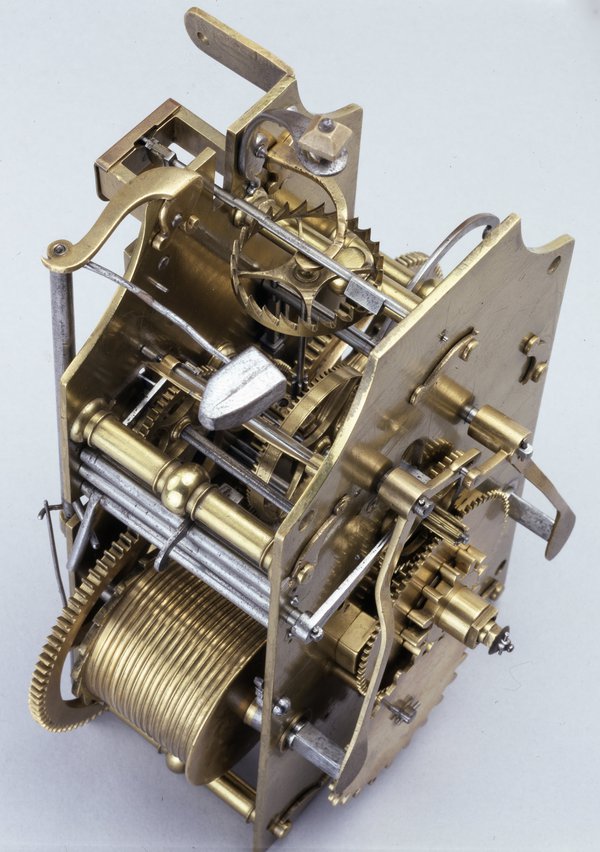

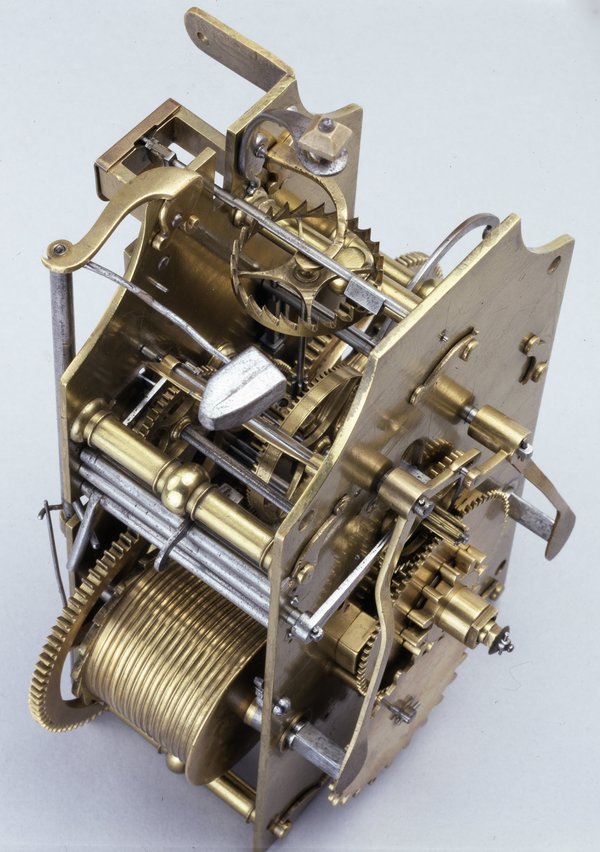

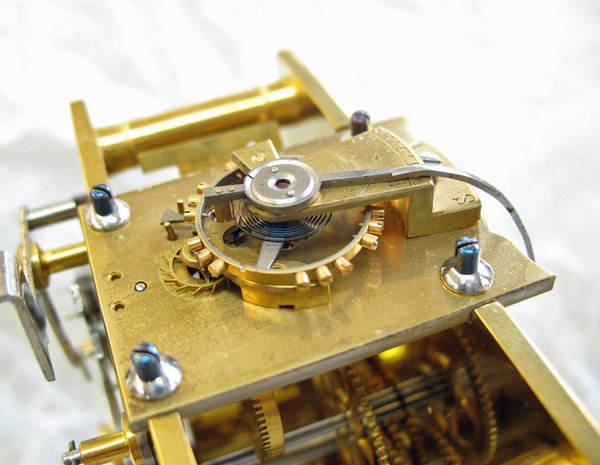

Next, an interesting year-going movement. This was probably housed in a slate or marble case, perhaps something like this.

The inscription on the dial is somewhat rubbed and not wholly legible, but it seems to be signed for Edward Watson of King Street, Cheapside, London (working 1815-63) who would have been the retailer for the clock.

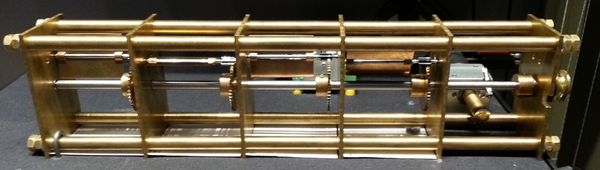

The movement is stamped to show that it was made by Achille Brocot of Paris. Brocot invented this type of long duration movement in the mid-19th century, employing multiple mainsprings in going barrels to drive the clock.

The system has great advantages over using a single large mainspring to achieve a long duration. Smaller springs are easier to make and much easier to remove for maintenance. Also, if one of the five springs were to break it would cause far less damage to the clock than a recently-wound single spring with a year’s worth of driving energy being unleashed.

… and finally, an unusual and incredibly useful screwdriver. It has five slot heads at different orientations enabling access to those awkward screws, such as between the plates of a movement.

Right, I’m off to attend to a newly-installed longcase clock which has stopped – an in-situ adjustment of the back cock should do it..!

As with all items in the collections of the British Museum, these items are kept to be made accessible to all members of the public. An appointment to study them can be made by contacting the horological team at horological@britishmuseum.org or by telephone (020 7323 8395).

BHI Clock & Watch Conservation and Restoration Forum, 5th September 2015

This post was written by Oliver Cooke

Earlier this month the British Horological Institute hosted a day of lectures and discussion relating to horological conservation and restoration at their headquarters in Upton Hall.

![Upton Hall, headquarters of the BHI (Image: Andy Stephenson [CC BY-SA 2.0 (http://creativecommons.org/licenses/by-sa/2.0)], via Wikimedia Commons)](https://ahs.contentfiles.net/media/images/Upton_Hall_-_geograph.org_.uk_-_4563-1.width-600.jpg)

The terms 'conservation' and 'restoration' are applied to different philosophies of approach to maintaining and repairing objects.

Conservation typically describes an approach of minimal intervention, i.e. attempts to preserve the existing material of a clock or watch as far as possible, whilst still enabling it to serve its required use.

Restoration can describe attempts to revert a clock or watch (that has received alterations over the years) back to its conjectured original state. This typically involves involves the alteration or removal of existing material which, even if not original to the object, can be considered to be part of its history.

There are proponents and opponents of each approach, with many falling somewhere in-between.

There is no black or right – every conservation project is different. The differing motives of the stakeholders (who might include horologists and their clients, or visitors to a museum) and the intended use of an object are all valid considerations in the decision-making process which affects the outcome of a project.

The forum aimed to explore these issues through a series of talks from professionals in the field.

The AHS was very well represented with six of the seven speakers being members:

Ken Cobb – Welcome and Introduction

Alison Richmond – ICON’s Perspectives

Matthew Read – Conservation Training and Education in Horology

Oliver Cooke – Managing Dynamic Objects in Museum Collections

Chris McKay – Conservation on Larger Objects (Turret Clocks)

Keith Scobie-Youngs – Working with Others – Project Management within Conservation

Jonathan Betts – Conservation/Restoration for the National Trust and Other Heritage Organisations

The forum ended with a positive and interesting open panel discussion.

One of the key messages of the day was that the BHI and all horological practitioners have a key role in helping to educate, as widely as possible, all stakeholders in the conservation process on these issues because only with this knowledge might they know how their decisions in the present will affect our heritage in the future.

The forum was thus a very positive contribution towards this vital aspect of antiquarian horology and Kenneth Cobb and the BHI must be lauded for making it happen.

Can bonded solid lubricants preserve the teeth of running clocks?

This post was written by Oliver Cooke

Antiquarian clocks are still in widespread use. However, like any machine, mechanical clocks wear out as they run and, to keep them running, repairs will inevitably be necessary.

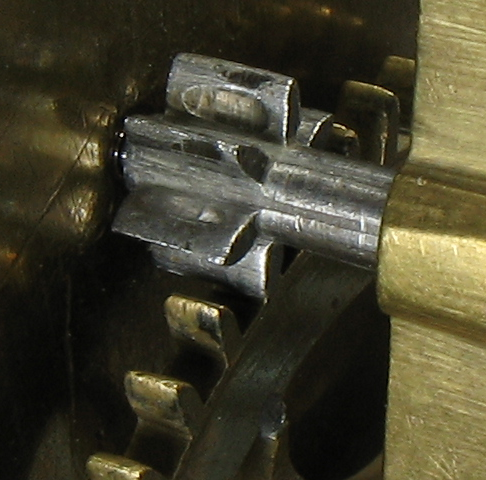

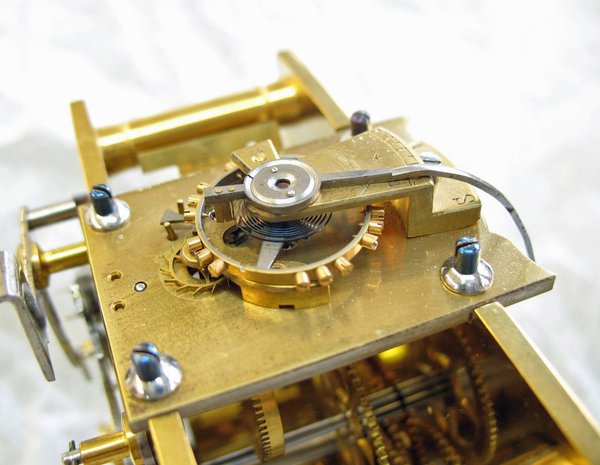

The image above shows a three century old longcase clock pinion that is well worn. Such a change in form will hinder the correct running of the clock until, eventually, it may no longer run at all.

Current repair techniques involve replacing the lost material or the whole gear. Either method is likely to result in loss of evidence of the clockmaker’s original work. This information is important as it can help us to assess the authenticity and origins of clocks.

It would therefore be useful to find a way to reduce the wearing of the teeth in the first place.

Liquid lubricants, e.g. oils, are generally not used on the teeth of clock gears as they are typically exposed to the air, from which dust can mix with the oil to form an abrasive, or chemicals can form which can corrode gears.

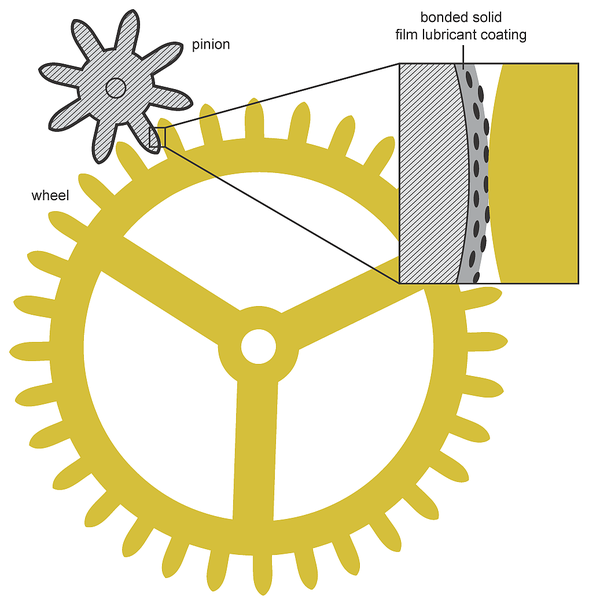

Bonded solid lubricants (B.S.L.s) are dry and do not absorb contaminants from the air. B.S.L.s contain particles of dry lubricant, such as graphite, suspended in a binding agent, such as epoxy resin.

They are applied as a liquid which cures to form a hard, dry coating. This coating can both lubricate and act as a sacrificial wearing layer. B.S.L.s might therefore be a useful treatment for preserving the gears of clocks.

Over the last year at the British Museum, where we run antiquarian clocks in the gallery, I have been conducting trials of B.S.L.s on model gear teeth as part of an MA Programme in Conservation Studies at West Dean College.

The B.S.L. that was tested was found to reduce wear compared to uncoated gear teeth. However, scientific analysis showed that it contained chemicals that are unsuitable for use on historic parts.

There are however many other types of B.S.L. and, given the promising results, I plan to test more. It is hoped that this will eventually lead to a treatment to help to keep the antiquarian clocks running with their original gears.

Look out for more information in future editions of our journal, Antiquarian Horology.

Keeping in touch with time

This post was written by Oliver Cooke

A common feature of watches and clocks of the 16th century are touch-pins. These are raised studs located at each hour position on the dial, with that at the 12 o’clock position typically being longer and sharper to provide a point of reference.

These enable the time to be read by feeling the position of the single, robust, hour hand.

This was useful as it was not possible to simply switch on a lamp to read the time at night. An added benefit might have been that the time could be read discretely under one’s robes.

This is a later variation of touch indication, known as a “montre à tact” (“touch watch”).

The exposed hand does not turn with the movement but it is moved manually, clockwise, until it stops at the right time. This is read against touch-pins that are located on the edge of the case.

These watches are also sometimes known as “blind-man’s” watches but, although they could have served as such, they were conceived as night watches.

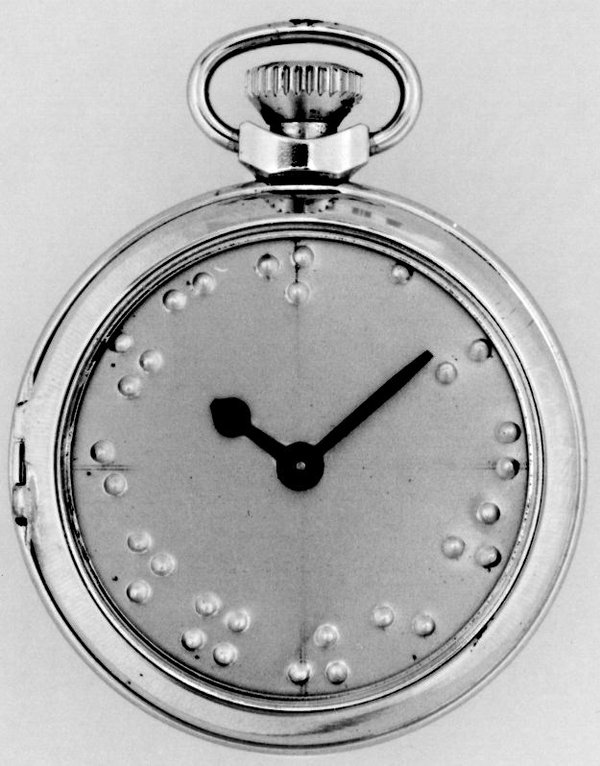

This watch, however, was clearly designed to be used by visually impaired persons as it has Braille numerals on the dial.

Mass production of watches and clocks became established in the 19 th century and it enabled them to be affordable to the masses and, subsequently, the massive new market enabled a much greater variety to be economically viable, including this Braille watch.

This wrist-watch bears the latest incarnation of touch indication.

The time is indicated by steel ball bearings which run in tracks, positioned by magnets driven by the movement within the case – the hours around the perimeter and the minutes on the front of the watch.

The balls are easily displaced, which prevents damage to the movement, but are easily relocated with a twist of the wrist.

The watch was conceived for use by visually impaired persons, but its elegant design appeals to a far larger market. The development of this watch somewhat parallels that of the Braille watch, as it also depended on a fundamental development in technology and economics.

This watch was brought to market through internet “crowd-funding”, whereby many individuals invest a relatively small amount each to raise the total capital necessary to fund the development of a product (in this case enabled by Kickstarter). Crowd-funding can enable some exciting projects to succeed which might have been rejected by more traditional investors.

Look no hands!

This post was written by Oliver Cooke

On the one hand we have looked at single-handed dials, on the other hand we have looked at some more unusual forms of indicator. Here we will look at indicators with no hands at all.

This watch has a display with digits formed of light emitting diode (LED) segments, seven for each numeral.

LED watches were first introduced in 1970 by the Hamilton Watch Company and were soon followed by liquid crystal display (LCD) watches. LED and LCD were by no means the first technology to enable digital displays however.

Before these examples existed the 'wandering hour' dial, something of a mash-up of digital and analogue time indication.

The hour numeral wanders, from the left-hand position (as viewed), up-and-over the semicircular aperture during the course of an hour. As the current hour ends and disappears behind the dial plate, the next hour numeral appears on the left.

We see 12:14 indicated on the illustrated example.

The system was invented in the 1650s by the brothers Tomasso and Matteo Campani from San Felice in Umbria, as a means to enable the time to be read at night (the numerals are pierced, allowing the light of an oil lamp to pass through from behind). This was very useful in the days before instant electrical lighting.

The wandering hour dial was also, occasionally, used on watches in the late 17th century, (but an oil lamp was not fitted in these!)

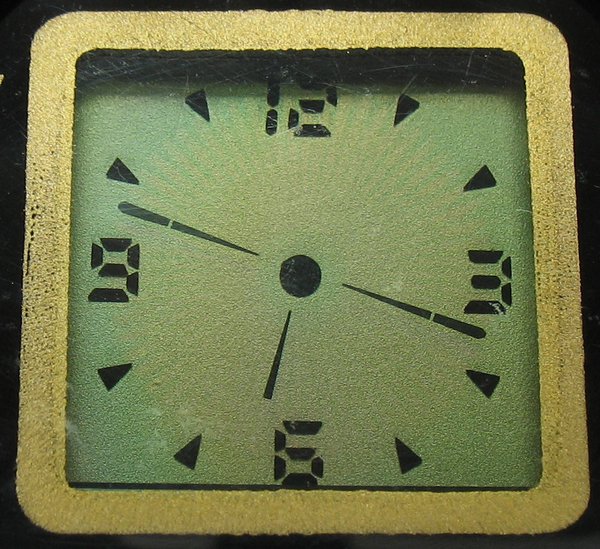

Finally, this watch also blurs the distinction between analogue and digital.

It has an LCD but, instead of digits, it has radial segments representing hands. This, however, requires 120 segments instead of the 42 needed to make up a standard six-digit digital display.

Together with the corresponding electronics needed to drive each segment, this means that these “LCA” watches cannot be made as cheaply as their digital counterparts. Perhaps for this reason they have never been popular, but they must have an adequate, if small, number of fans as they seem to have always (just) remained in continous production by one manufacturer or another since the 1970s.

I wonder how many of their fans, like I, appreciate them mostly for the futility of over-engineering, to achieve a result with LCD that is much more easily and better obtained with physical hands!

…on the other hand

This post was written by Oliver Cooke

On the one hand we have simple, easy to use, single-handed dials. On the other hand, some dials are not so straightforward.

This clock has 'fly-back' or 'retrograde' hands. The hands proceed clockwise as usual but when they reach the end of the scale, each will spring back and then immediately resume its count.

This design allows the dial to have twice the diameter of a circular dial within a given height. This, together with the semi-circular form, makes these clocks suitable for positioning over doorways and they were sometimes integrated within wall panelling.

Fly-back hands are still a popular feature in watches, although these are usually (but not always) the preserve of high-end watches.

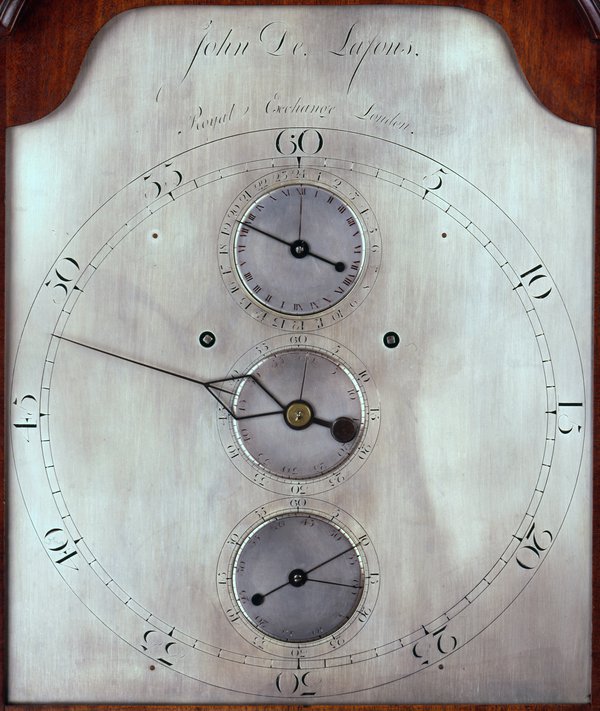

The dial of this regulator (that I have mentioned before for its escapement) has the typical features which facilitate the use of these clocks in observatories and laboratories. All hands are positioned on their own centres for disambiguation. The hours are relegated to a small subsidiary dial and only the minutes have a large hand, for accurate observations.

Less typically, however, this regulator indicates two different systems of time using only one set of hands.

It shows mean sidereal time against the numerals on the main dial plate and mean solar time against the small discs. A mean sidereal day is 23 hours 56 minutes and 4.1 seconds, i.e. it is about 4 minutes shorter than the 24 hour mean solar day. The discs rotate slightly faster than the hands so that after each day they have accrued the 4 minutes difference. This system is called a differential dial.

Having a clock show both sidereal and solar time might have been a convenience, but a respectable observatory might well be expected to have had separate regulators for providing the required times and so it is possible that this design may have been conceived rather for the use of the (wealthy) amateur.

This watch has not just hands, but arms and fingers too! It is a type of watch known as “bras en-l’air”, which translates as “hands in the air” (and certainly not “bras in the air” – which might apply another aspect of horology altogether). When the pendant is pushed the soldier raises his arms, holding pistols to point at minutes (left) and hours (right).

On the one hand

This post was written by Oliver Cooke

The last of the five elements is the indicator, the part of the clock or watch that conveys the time.

Early clocks and watches typically only had a single, hour, hand. This was more than adequate for indicating the time as these foliot-controlled timekeepers would typically lose or gain at least quarter of an hour in a day. Minute and seconds hands only became truly useful with the vast improvement in timekeeping that came with introduction of the pendulum in 1657 and the balance spring 1675.

However, the familiarity, simplicity and economy of the single hand meant they never became obsolete. Throughout the 18th century, pendulum-controlled longcase clocks with single hands were very popular in the provinces of England.

There were also some more interesting implementations of the single hand. This balance spring watch has a six-hour dial, instead of the usual twelve-hour dial. With only six hours dividing the circle it offers twice the resolution of a standard twelve-hour dial, thus going some way to making up for the lack of a minute hand.

Next, a single hand with a difference – it is telescopic. The hand extends and retracts to follow the contour of the oval dial, allowing the time to be read clearly. A fixed hand would fall short at the “XII” or “VI” positions, making it harder to read with accuracy.

Another form of single hand can be found on this Japanese pillar clock.

The pendulum controlled movement is at the top of the clock. Below it, the single, hour, hand is directly attached to the driving weight through a slot in the case. As the weight descends over the course of a day, it indicates the time against the linear scale of numeral plaques on the case. The plaques can slide, which allows their positions to be adjusted for the Japanese system of unequal hours.

Single handed watches continue to made by several manufacturers, such as this example owned by myself.

In practice, the time can only easily be read to the nearest five minutes (which is well within the capabilities of its modern movement). However, I find that this is good enough (at the the weekends at least!) and it is a most leisurely way to follow the time.

Freak control

This post was written by Oliver Cooke

Continuing our wander through the five elements, we come to the controller – the part of the clock which controls its rate. Let us pass-by the major landmarks (the pendulum, the balance spring and wheel and the quartz crystal) and seek an alternative trail.

With their origins preceding mechanical clocks, compartmented cylindrical clepsydrae (shown in a previous post for their silent operation) have a drum which rotates and descends. Water passes between compartments inside the drum, controlling the rate of rotation.

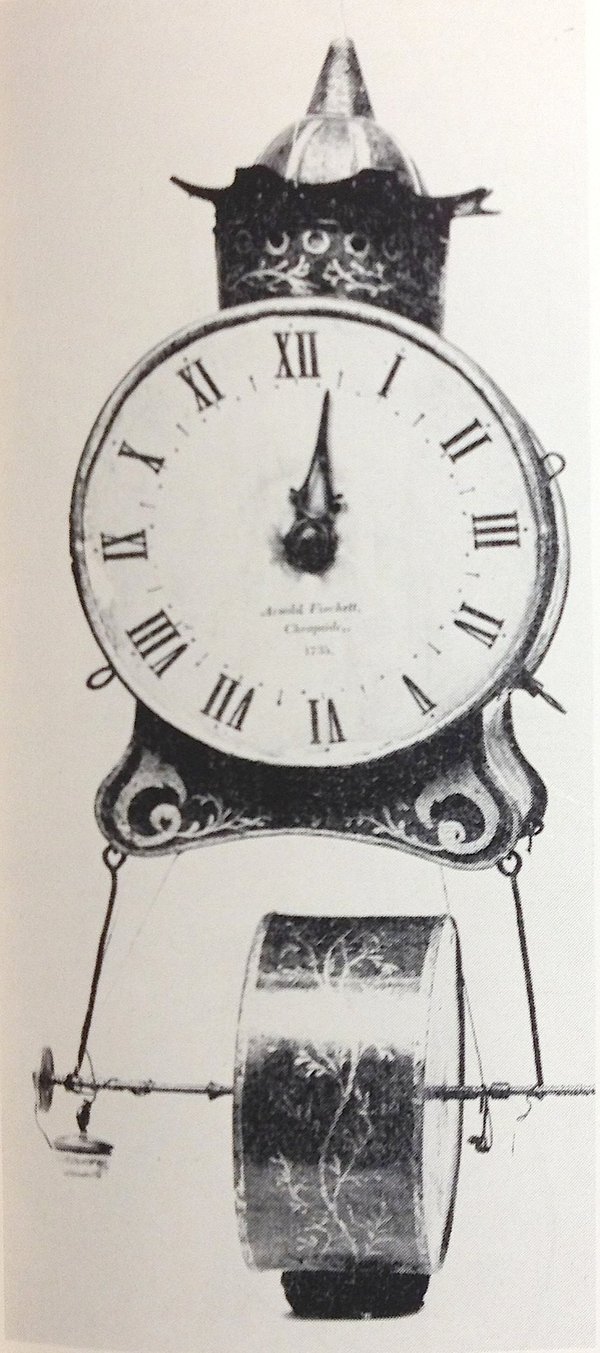

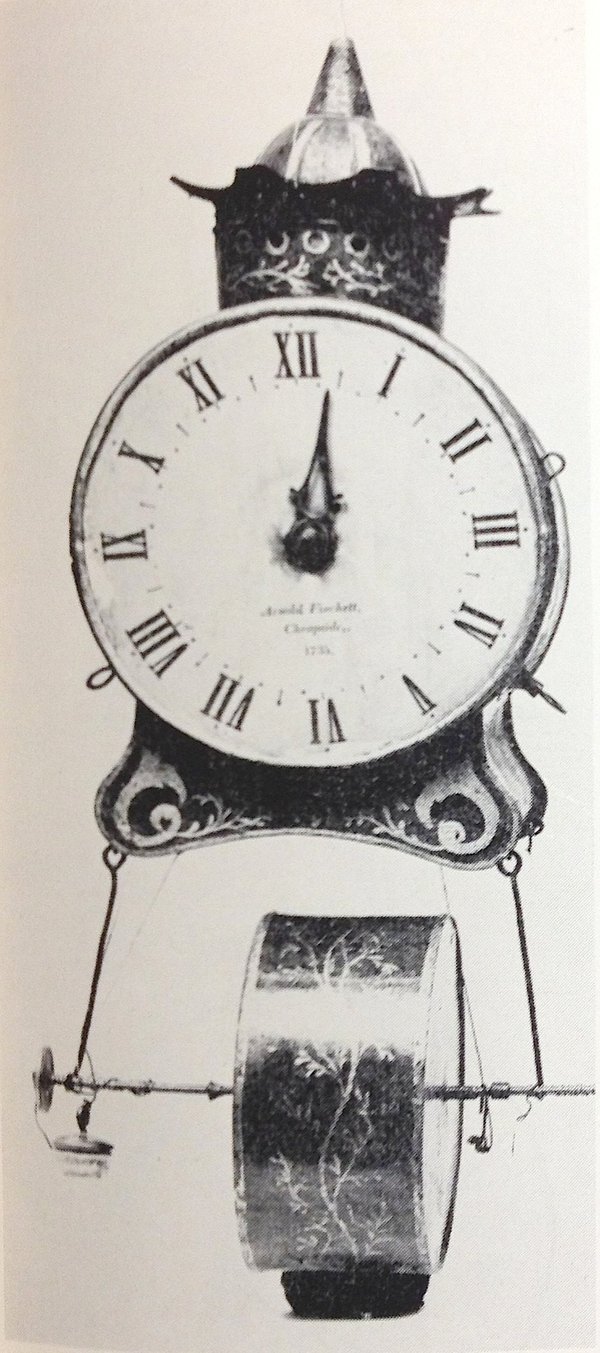

These were recurrently popular at various times in history and were incorporated in clocks, such as the example illustrated here which was made by Arnold Finchett, London, c.1760. The drum, connected by a line, drives the hand on the dial. This system is reported to provide reasonable timekeeping (at least in non-freezing conditions)!

Sir William Congreve (1772-1828) patented his inclined-plane rolling-ball clock design in 1808. Its ball bearing zigzags down a track on the table and actuates a lever at the end of its travel, causing the table to see-saw and the ball to roll back again.

In the example illustrated here, each leg takes thirty seconds. Despite being largely detached from the influence of the movement, the progress of the ball is hampered by any irregularities on the track, generally resulting in awful timekeeping (rather like my daily commute).

Nevertheless, the clock is mesmerising and surveys show that it retains the attention of visitors longer than any other exhibit in Djanogly horological galleries.

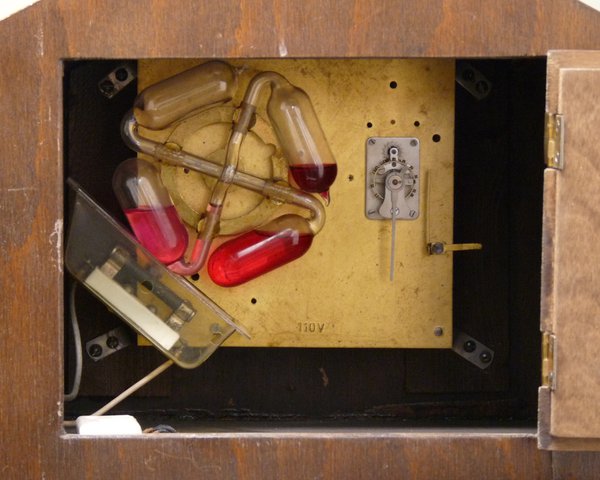

Another clock shown before is the Smiths “Sectric” electric mantel clock. The clock motor is synchronous – i.e. its speed depends on the (very stable) frequency of the alternating current of the mains supply, which thus effectively controls the rate of the clock.

These clocks were very popular from 1930s but were superseded by quartz technology from the late 1960s, largely for the convenience of battery power, which avoided the need for wiring.

Finally, from 1960 Bulova produced their 'Accutron' watches which incorporated a tuning fork to control their rate. The steady hum of the tuning fork can clearly be heard when the watch is held to the ear.

Despite being excellent timekeepers and very popular, within ten years the introduction of superior and cheaper quartz watches rendered them obsolete.

Time and efficiency

This post was written by Oliver Cooke

Last time I looked at how clocks and watches obtain and store their energy, but I thought it worth mentioning how carefully they use it.

Some clocks are designed to have a surfeit of energy – for instance turret clocks must be able to overcome ice and snow loading. But, in general, efficiency is paramount in horology.

A 17th century eight day longcase clock typically runs on a 12lb weight (5.44kg in new money) which drops about 5 feet in the eight days. Based on those numbers, my dimly recollected school physics tells me that such a longcase clock must use about 1/8500th of a Watt of power.

Let us compare that with something familiar. The best example I can think-up is the motor that vibrates a mobile phone – these run at about 0.16W – i.e. that little motor that tickles in your pocket could run about 1500 longcase clocks. Or, looking at it another way, the energy used to boil an egg would keep a longcase clock going for 80 years. Not bad for a 300 year old machine.

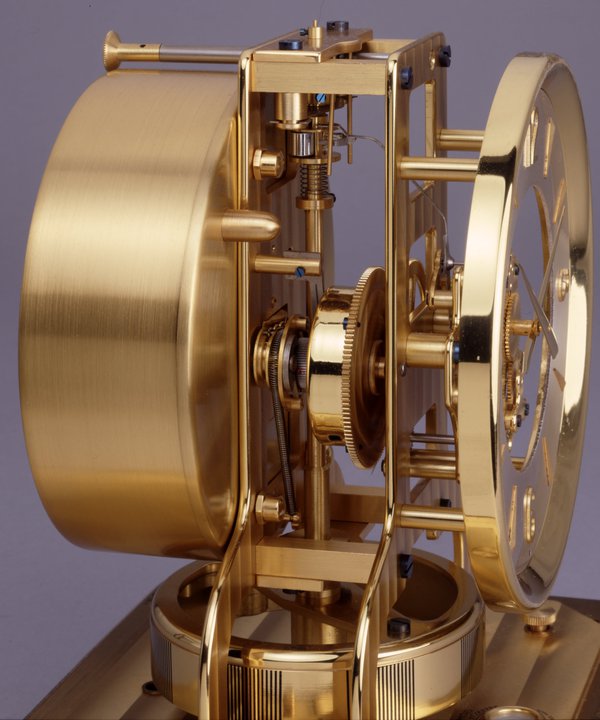

The Atmos clock (which I mentioned before for its ability to be powered by changes in air temperature) is in another league – the little mobile phone motor could run 700,000 of them. 1 boiled egg, 38000 years.

How are they so much more efficient than the longcase clock? Apart from being closer in scale to watch work, the Atmos clock benefits from 250 years of horological development. They are factory made, not hand made – this facilitates much closer tolerances and optimal gear tooth shapes. Like fine watches, their bearings are jewelled (jewels are little rubies with holes drilled in them – very smooth and very hard wearing). They also have a steel torsion pendulum which is excellent at conserving energy.

Something else to bear in mind is that we expect our clocks and watches to run non-stop for years on end, between services, without breaking down. Do you ask the same of your car? Remember that when your clock repairer presents their next bill to you!

Power madness

This post was written by Oliver Cooke

In a previous post I explained how mechanical clocks and watches work, with five elements – energy, wheels, escapement, controller and indicator. Let’s explore how some clocks and watches get their energy.

Mechanical clocks and watches employ kinetic energy, drawn from a built-in reserve – usually a mainspring (elastic potential energy) or a driving weight (gravitational potential energy). However, these need to be replenished, or wound-up.

We commonly wind-up a clock or watch directly, with kinetic energy from our muscles (which, before that, was chemical energy from our breakfast). In an automatic watch, a moving weight spins and winds it up as we move around.

In c.1765, James Cox made a clock that is wound by changes in atmospheric pressure. Similar is the Atmos clock, which has gas-filled bellows which expand and contract with changes in the surrounding air temperature and pressure – this movement winds the spring in the clock. This has been a very successful design – it was first introduced in 1928 and it is still being made. There was even a mechanical clock made to be powered by by an artificial heat source (see image).

Electrical clocks and watches employ electrical energy. We might provide this by putting in a fresh battery (which is a reserve of chemical potential energy), although sometimes the battery is rather larger than the clock it powers!

Mains powered clocks often do not have a built-in energy reserve and so these are reliant on a continuous supply to keep going. Solar powered clocks and watches use solar panels to convert light to electricity, which then charges a battery – this reserve is essential as the power source is not reliable – e.g. day and night.

So, those are a few examples of how clocks and watches can obtain the energy they need. Of all the types of energy I can think of, only sound and atomic energy have not been not used to directly power clocks and watches. As to how they exploit the energy… well that is another story altogether… maybe for a later post!

Do clocks tick you off?

This post was written by Oliver Cooke

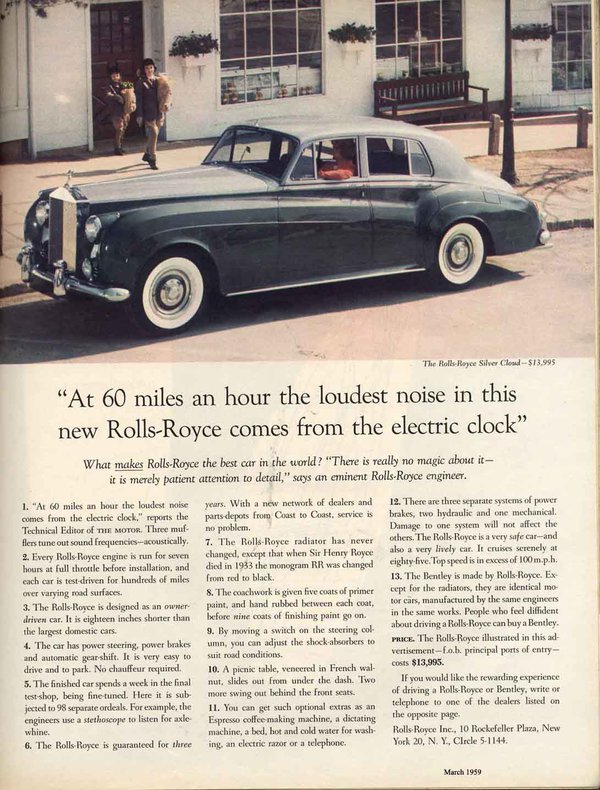

In his book Confessions of an Advertising Man, originally published in 1963, David Ogilvy calls this ‘the best headline I ever wrote'.

Interestingly, in a footnote he adds: 'When the chief engineer at the Rolls-Royce factory read this, he shook his head sadly and said “It’s time we did something about that damned clock!"'

I previously explained that the ticking of a timekeeper is the sound of the escapement stopping a wheel tooth. But why is the ticking of a clock music to some and unbearable to others?

Loudness is a common complaint. The farther and harder the tooth drops before it is stopped by the escapement, the more energy is lost to sound and the louder it will be. This will tend to increase with size, but energy loss can be minimized with an efficient design and good construction. Also, the rest of the movement and its case can act to either attenuate or amplify the sound.

The timbre of the sound can be soothing or grating. Just like the character of a violin is much more than the pure tone of its vibrating string, we are not hearing just the escapement – the construction of movement and case all contribute to the texture of the sound.

Another aspect is the timing of the ticks – the beat of the clock. An uneven beat probably offends everybody. If, instead of an even 'tick tock tick tock tick tock', you hear 'ticktock… ticktock…. ticktock…' (or even tocktick!) then your clock is out of beat. To fix this, make sure the clock is level, otherwise your repairer can easily sort it.

Some examples:

Some clocks were designed to reduce escapement noise. Some of these had so-called 'silent escapements' in which more compliant materials were used (such as spring steel and gut line) to absorb the impact. Pietro Tommasi Campani invented an impact-free crank escapement for use in his night clocks.

Avoiding escapements altogether, compartmented cylindrical clepsydrae were recurrently popular at various times in history. In quartz controlled clocks, the escapement is also eliminated, although many of those use physical hands whose driving motors can usually be heard, ticking or whirring.

Thanks to Peter de Clercq for inspiring this post and providing the piece on Ogilvy.

The basics – how a timekeeper works

This post was written by Oliver Cooke

Old clocks and watches are fascinating even without knowing how they work, but just a simple explanation provides a much deeper appreciation.

The timekeeping function of mechanical timekeepers can be explained as just five elements:

1 – Energy Source

All machines, including timekeepers, need energy to work. The energy is usually stored in a weight or spring. When it is wound, energy is transferred from our muscles and into the driving weight (as it moves up against the force of gravity) or the mainspring (as it tightens-up). This energy is released into the timekeeper as the weight drops or the mainspring unwinds.

2 – Wheels

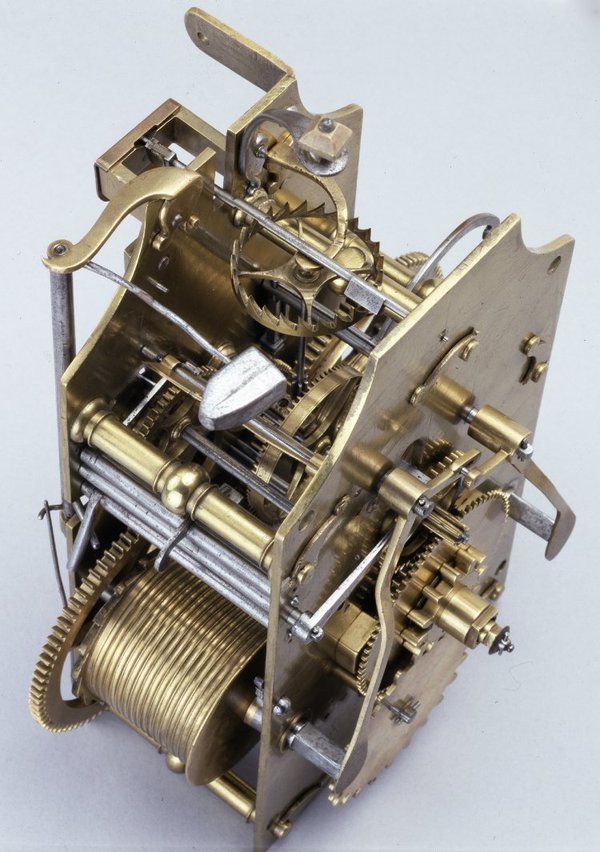

An interconnected series of toothed wheels and pinions, known as a train, transmits the energy through the timekeeper. The energy source moves slowly and the wheel at the furthest end of the train moves quickly. This is the opposite of a car gearbox, where the engine revs quickly and the wheels on the road rotate more slowly.

3 – Escapement

The escapement is connected to the quickly moving end of the train of wheels. Like a turnstile which allows one spectator through at a time, the escapement allows one wheel tooth to pass through (or 'escape') at a time. Without it, the wheels would whizz until the weight hit the floor. The ticking of a timekeeper is the sound of the escapement stopping a wheel tooth.

4 – Controller

The controller is connected to the escapement – it controls the rate at which it allows the teeth to pass through. As each tooth passes the escapement, it gives the controller a little push to keep it going. A common controller is a pendulum, which is just a hanging weight – give it a push and gravity makes it swing, at a steady rate. Because gravity is very constant, pendulums are great for good timekeeping.

5 – Indicator

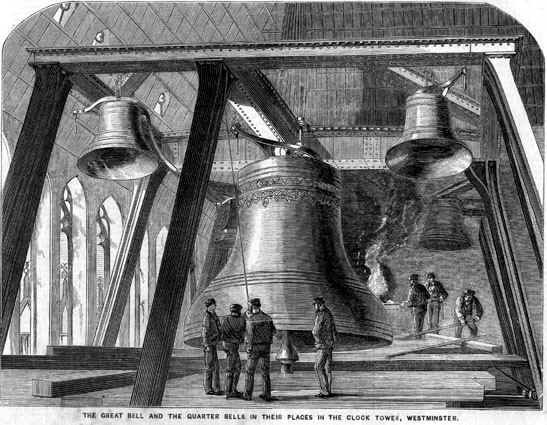

The part of the timepkeeper that tells us the time. Most familiar are hands on a dial. A clock striking a bell gives an aural indication of time – sometimes from many miles away.

These five elements apply to (almost!) all mechanical timekeepers from the most ancient to the modern. They can vary wildly, but are there if you look!

PS This superb website has interactive animations showing how escapements (and some other horological bits) work.

Where can I see antiquarian horology?

This post was written by Oliver Cooke

I refer not to our society’s journal (which you can of course see by joining us!), but where can we see old clocks and watches?

I clearly remember dearly wanting to know this information when I first became properly interested in horology. Now I am in the loop and am l pleased to be able to share some good tips.

There are the major collections in national museums; the British Museum, the Royal Observatory Greenwich and the Science Museum. But since these are well-known, let their plugging end there for now and let instead us look at a couple of less well known collections from different ends of the country.

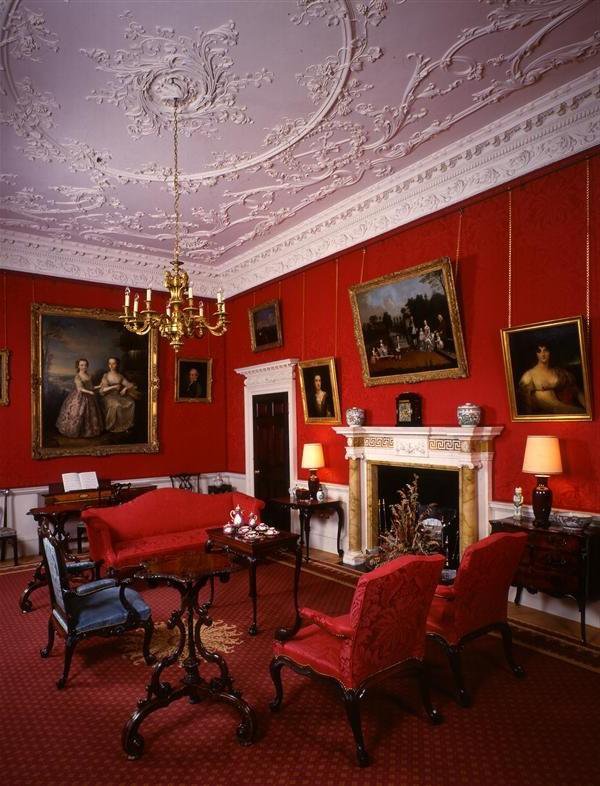

Starting down South, there is the finest private collection outside the institutions mentioned above – the Harris collection, in Belmont House in Kent. The collection is wide ranging with examples from all the major clock making countries and periods, but there is a strong focus on England’s horological ‘Golden Age’. Not only does the house have its collection, but it is a beautiful place to visit in its own right – it is a magnificent neo-classical house set in beautiful gardens in the North Downs.

So, if you have a partner who likes horology a little less than you, they will not be disappointed when joining you on a visit there. Jonathan Betts, sometimes author on this very blog, conducts a clock tour at 1.30 pm on the last Saturday every month during the season. Prior reservation is necessary – please see the Belmont House website for details.

Now, heading up North, another great place to visit is Fairfax House in York. Fairfax Houses houses the collection of Noel Terry (grandson of the founder of the confectionery firm), one of the finest private collections of the twentieth century.

Again, this House has much more to offer than just clocks and watches and of course it is bang in the middle of York, a city worth a visit in its own right. The house is open every day except Mondays for most of the year – do check their website.

There are more collections to tell of, which can follow in a later post. Keep reading!